A split fiber laser marking machine stands out for modern enterprises in marking and engraving with precision, efficiency, and scalability. From manufacturing and jewelry design to automotive and electronics, these machines serve as a multifaceted solution for varying industrial requirements. But what exactly are their distinguishing features? This blog will discuss why you should incorporate a split fiber laser marking machine into your operations. Along with cost savings, unrivaled accuracy, and unmatched productivity, this technology offers critical advantages that can change how businesses operate in today’s competitive environment. Continue reading to learn how this advanced innovation can transform your work processes.

What is a fiber laser marking machine?

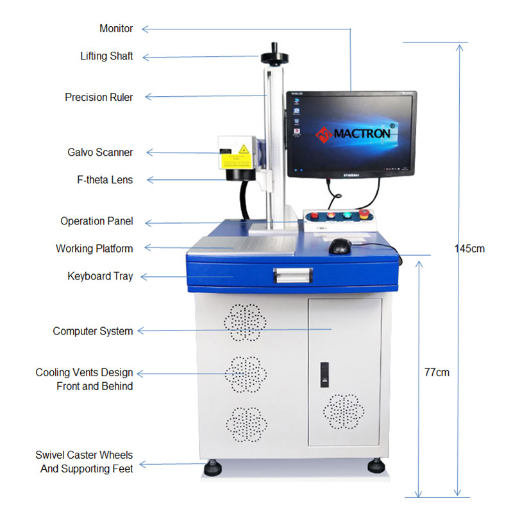

The fiber laser marking machine uses fiber lasers to mark different types of materials, such as metals, plastics, and even ceramics, with marks that are both precise and cannot be removed over time. This machine works by targeting the surface of the cued material with an exact laser. It focuses on a particular point on the material so that it can either undergo a physical or a chemical change, enabling it to engrave words and text. Some examples include logos and barcodes. Besides these attributes, fiber laser machines are well known for being highly accurate and not taking much time. This is why they are used worldwide in different industries, including automotive and electronics. The marks that these machines put are apparent. Most importantly, they do not ruin the material’s quality.

How does a fiber laser engraver work?

A fiber laser engraver uses a beam of light concentrated through a fiber optic medium, which laser amplifies and focuses onto a specific material’s surface. The engraving process begins with generating a beam in the seed laser, followed by further amplification using fiber optics containing rare-earth elements like erbium, neodymium, or ytterbium. The fiber optics increase the laser’s power, assuring precision interaction with the material’s surface.

During engraving, lasers vaporize over 1,000°F (540°C) surface level, leading to micro-ablation or melting, thereby etching unmatched intricate and clear marks onto the surface. Fiber laser engravers can reach line widths of 0.01 mm, which is why they are preferred for micro-detailing work.

Moreover, modern etching machines are equipped with fiber lasers and advanced galvanometer-based scanning systems for high-precision fiber laser etching. In some cases, marking speed achieves over 7,000 mm/s while maintaining precision. Galvanometer scanning is less power-intensive than other methods, ensuring laser etching machines are over 30% efficient, in comparison to CO2 lasers, which use significantly more power than these machines.

Fiber laser engravers work with various components, including metals like aluminum, stainless steel, gold, ceramics, plastics, and select composites. The markings made by engravers withstand damage from wear, corrosion, and high temperatures, and thus are long-lasting. Engravers are regarded as essential tools across different industries because of their accuracy, remarkable speed, and versatile operations, including specifying medical devices or aerospace engineering.

What materials can be marked with a fiber laser?

| Material | Key Points | Parameters |

|---|---|---|

|

Aluminum |

Lightweight, absorbs laser well |

High laser power for efficiency |

|

Stainless Steel |

Durable, corrosion-resistant |

Use annealing to prevent damage |

|

Gold |

Easy to mark, no oxidation |

Precision for minimal wastage |

|

Silver |

Reflective, soft material |

Use pulsed lasers for contrast |

|

Titanium |

Strong, used in medical/aerospace |

Low speed, high precision |

|

Plastics |

Includes ABS, PVC, Nylon |

Low power to avoid melting |

|

Rubber |

Flexible, absorbs laser well |

Medium power for clear marks |

|

Ceramics |

Hard, requires precise marking |

Use etching for darker marks |

|

Glass |

Intricate designs possible |

High precision, low power |

|

Wood |

Coated wood works best |

Low intensity, slow speed |

What are the advantages of using a split fiber laser?

The fiber laser can mark a wide variety of materials with great precision. There are many materials that can be marked using fiber lasers:

- Metals

Fiber lasers are very useful for marking metals such as Stainless Steel, Copper, Brass, Aluminum, Gold, and Titanium. The marks can also withstand severe heat and corrosion.

- Plastics

Fiber lasers are non-damaging and mark with great precision. Thus, many plastics, such as polycarbonate, USB, Polypropylene, and Acrylic, can be marked.

- Ceramics

Fiber lasers are capable of marking ceramics like Silicon-Carbide or Aluminum-Oxide. These marks are both permanent and precise.

- Composites

Composite materials mark accurately and without causing any damage. Due to their strength and light weight, they are used in multiple industries.

- Coated Materials

Lasers also effectively mark coated materials, such as anodised Aluminum or other painted surfaces. The marks often reveal the base layer.

Unlike other lasers, fiber lasers can mark various materials with high durability, making them extremely versatile in the industrial field.

Choosing the Right Laser Engraver?for Your Needs

Selecting a laser engraver requires examination of individual specifications, as each machine serves a different purpose. Determine what the primary material is first. It can be metal, plastic, or even a coated surface. Then set the requirements for how precise and quick you would need the engravings done. Fiber lasers are the best choice for the best engraved details on metals and coated surfaces. CO2 lasers work best with wood and acrylics, which are non-metal materials. Pay attention to the machine’s physical dimensions so that it can fit in the workstation and ensure it is spacious enough for the projects. Finally, estimate the expenses and assemble a list of reputable brands with good after-sales services to provide value in the years to come, and assist in guaranteeing value down the line.

What is the difference between a?20W?and a?30W fiber laser?

| Feature | 20W Fiber Laser | 30W Fiber Laser |

|---|---|---|

|

Power Output |

Lower power, suitable for light tasks |

Higher power, handles tougher tasks |

|

Marking Speed |

Slower marking speed |

30% faster marking speed[^1] |

|

Marking Depth |

Up to 1mm depth |

Up to 1.5mm depth[^1] |

|

Material Compatibility |

Thin materials, light metals |

Thicker materials, deeper engravings |

|

Engraving Area |

Max 175x175mm |

Max 200x200mm[^3] |

|

Precision |

Adequate for small-scale tasks |

Higher precision for larger areas[^3] |

|

Cost |

More affordable |

Higher cost due to power[^1] |

|

Energy Consumption |

Lower energy usage |

Higher energy usage[^1] |

Should I opt for a 50W split fiber laser?

Engraving, cutting, and marking, especially with metals and hard materials, become easier with the 50W split fiber laser as it delivers high power performance. Higher-wattage fiber lasers are less efficient and slower in processing than their lower-wattage counterparts. Still, the 50-watt split laser is specially designed to achieve speed and efficiency for industrial or large-scale projects.

Laser engraving and carving into materials like metal gets easier with the 50W split fiber laser as the design allows for deeper engraving in less time, which is exceptionally beneficial for time-sensitive projects. For more specific results, the 50W fiber laser is optimal as it gives clean, sharp, and defined results compared to the 30W models. Not only does it deliver in power, but the design is space efficient as the source and marking head are separate, allowing for more flexibility.

The 50-w laser can also work on bigger working areas and is used for various applications, from intricate engraving to cutting thicker 1mm brass and 2mm aluminum. Recent performance evaluations show that 50W fiber lasers can process some materials 40% faster than the 30W models. However, It is necessary to consider that increased power also translates to higher energy consumption and upfront costs.

Overall, choosing the 50w split fiber laser would depend on the scope and nature of one’s work. For those whose work entails higher-volume precision work, the 50W laser investment would be ideal in terms of efficiency, value, and, most importantly, longevity. As with any business decision, determine your exact requirements, budget, available space, and needs before making a decision.

How to select a laser marking machine based on the working area?

The working area determines the maximum engraving area on a material, and depending on the type of applications you intend to handle, the size of the materials will also be important. The working area impacts productivity and efficiency since it determines the maximum dimensions of the material that can be marked within a single process.

Small Working Area (100mm x 100mm or smaller): These beasts fit conveniently into spaces, perfect for precision tasks such as tool engraving or the jewelry class of electronic components. Their high-detail CNC machines are well-tailored for sectors with absolute precision demands.

Medium Working Area (200mm x 200mm to 300mm x 300mm): This class is most popular in general engineering, automobiles, and many other electrical businesses. These can be multi-purpose devices for marking, capable of marking logos on metal or engraving medium-sized tools and equipment. This is the most popular size due to its versatility.

Expansive Working Area (400 mm x 400 mm or greater): For projects that require marking large sheets, panels, or components, bigger working area machines are vital. This is common in the aerospace and signage manufacturing industries. A larger working area minimizes the time-wasting process of repeatedly repositioning materials, enhancing productivity.

- Insights and Data of Industries:

- Based on the industry’s demand trends, Laser marking machines with a working area measuring 200mm x 200mm continue to be the most popular due to their versatility across materials and industries. However, there are rising demands for machines with larger working areas, especially in industries that handle large parts or batch processing.

- Current models also incorporate newer developments such as 3-axis dynamic focus technology, which enables the machine to adjust to the contours of curved or uneven surfaces, thus enhancing the effective working area beyond its actual dimensions.

- Evaluate the sizes, types, and volumes of materials in production when opting for the right working area, especially for a laser cutting machine. As a general rule, bigger working areas mean greater costs and enhanced floor space, so these considerations should aid in balancing decision-making.

Applications of split fiber laser engraving

Split fiber laser engraving is popular in many industries because of its accuracy and precision. Typical applications are marking logos, serial numbers, and barcodes on plastic and metal parts, doing detailed work on decorative jewelry pieces, personalizing tools, laptops, and desktop computers, and even mobile phones. In the automotive, aerospace, and medical industries, it is used to make permanent, high-quality markings. The varied amount of materials that can be engraved makes it suitable not only for bulk manufacturing but also for individual customization.

What industries benefit from laser engraving?

The application of laser engraving technology is very flexible because its accuracy and endurance can benefit a great range of industries. I will highlight five of these industries where laser engraving plays a critical role:

- Automotive Industry

The automotive industry extensively uses laser engraving technology for branding, marking serial numbers, and barcodes on auto parts. This enhances manufacturing traceability, quality control, and compliance with various legislative requirements. Laser engravings are durable and do not fade or become indistinguishable under rough conditions.

- Aerospace Industry

Extreme accuracy is needed in the aerospace industry, and laser engraving provides great precision when labeling and marking aerospace parts. Components, tools, and equipment are swivel-etched with unique IDs, increasing safety and streamlining maintenance procedures.

- Medical Industry

Hygiene, traceability, and longevity are essential requirements in the medical field. Various instruments, implants, and tools are in use that require permanent marking without impacting their usage; these can be marked with laser engraving. Markings include serial numbers, QR codes, or patient-specific details requisite for safety and compliance.

- Jewelry & Luxury Goods

Engraving with lasers is a modern marvel. It enables the engraving of intricate designs on luxurious items like watches, jewelry, and more. This process increases the product’s appeal by offering personal, artistic touches and enhancing value. High-end customization is best done with lasers because of their effectiveness on delicate details and precious metals.

- Electronics Industry

With the increasing popularity of electronic gadgets, engraving with lasers has become essential. This technology has enabled the marking of brand logos, labeling circuit boards, and serializing devices. Because of this technology, even delicate components found in consumer electronics have legible and precise markings.

The adaptability of engraving with lasers blossoms in these industries’ quests for efficiency, reliability, and precision, all while providing spectacular outcomes.

How is?fiber laser engraving used in metal and plastic?

The fiber laser has transformed the engraving of metals and plastics into a much simpler task because of its precision and versatility. Metals like aluminum, stainless steel, brass, and titanium are heavily engraved using fiber lasers. This process creates vastly contrasting marks, outstandingly durable and resistant to corrosion or wear. Fiber laser engraving is omnipresent in the aerospace, automotive, and jewelry industries for serial numbers, barcodes, and decorative engravings. Recent statistics estimate that fiber lasers can engrave up to 7,000 mm/second, which increases productivity in many industrial settings.

Regarding plastics, branding and product identification require detailed and permanent marks, which fiber laser engraving specializes in. This is achieved by altering the surface temperature of materials like ABS, polycarbonate, or acrylic with a powerful laser beam. Fiber lasers allow for the engraving of delicate or fragile materials without contact, which adds to their non-invasiveness. The medical manufacturing and consumer electronics industries heavily rely on this advancement. In comparison to other engraving technologies, fiber lasers are much easier to maintain, decreasing operational costs by nearly 30%, according to a 2023 study.

Laser marking is a recent technology advancement of laser engraving that precisely marks laser engravings and logos while optimizing energy use, speed, and accuracy. As a result, it is one of the most reliable marking methods for metals and plastics across various sectors.

Understanding the Technology Behind Laser Marking Machines

Machines marking materials with lasers use focused light beams to leave indelible identifications on items. This is done using engraving, etching, or annealing, in which a laser comes in contact with the material’s surface, changing it in some manner. Major components of these machines are a laser source, beam directing mirrors or lenses, and precision control software. Their effectiveness, uniformity, and ability to mark intricate designs have cemented their relevance and value in industries that need reliable, thorough identification or labeling.

What is the role of the laser source?

As you know, every laser marking machine has a laser source, which is integral as it generates the laser beam that marks and engraves the material. This marking laser needs to be very precise and strong to accomplish a wide range of tasks, therefore, it needs to be highly concentrated light which passes through amplifications. The type of laser source is based on fiber, CO2, and UV—and dictates their level of suitability for specific marking requirements and materials. For instance, fiber lasers are very effective for metals and plastics, while CO2 lasers work best on organic materials such as leather, wood, and paper.

Modern advances in laser technology focus on durability and efficiency. Unlike traditional fiber laser sources, modern ones have a life span with lower maintenance of 100,000 hours. Also, these devices typically have more than a 30% energy conversion rate, which means they are more energy-efficient. According to industry study data, marking speeds of more than 7,000 mm/s are achievable with modern source lasers, which significantly improves productivity in industrial locations. Therefore, when strategically optimizing the pulse of speed, laser quality, and energy output, this energy source should be considered as it can operate reliably throughout various uses.

What are mopa fiber lasers?

MOPA fiber lasers are an example of high-technology laser systems with a master oscillator from which the laser beam is produced and a power amplifier that increases the output. Different MOPA configurations have better control and fine tuning of power and precision boosting for both industrial and commercial use. MOPA lasers have fewer hardware restrictions and provide higher versatility, with much control over the parameters. In contrast, traditional Q-switched lasers’ control over tuning and ranging is extremely limited.

One key advantage of MOPA fiber lasers is their ability to produce pulse durations ranging from nanoseconds to milliseconds, enabling the processing of a broad spectrum of materials, including metals, plastics, and sensitive materials like ceramics. For example, finely controlled energy of MOPA lasers is highly suitable for color marking details on stainless steel, sharply defined marking on anodized aluminum, and finely machining delicate materials without transfer of heat damage.

New research shows that MOPA fiber lasers can mark up to 9,000 mm/s, which makes them more efficient than many traditional laser systems. In addition, these lasers have great energy efficiency due to their energy conversion rates of more than 35 percent, which further lowers costs and increases output power. With a high level of durability, these compact and maintenance-free lasers have an impressive lifespan of 100,000 hours. Their versatility makes these devices valuable in electronics, automotive, aerospace, and medical device manufacturing.

MOPA fiber lasers allow for advanced engraving and marking while providing exceptional control over the process. These features allow for unprecedented accuracy and precision, opening up new standards in MOPA fiber lasers.

How does laser power affect engraving quality?

The quality of an engraving is affected by the laser’s power, and this is very important. Personally, I believe that tougher materials benefit from deeper engraving, which is achievable with higher laser power because it renders the process quicker. Nevertheless, too much power can result in overheating, burns, or distortions. Finer details on delicate materials require lower power to maintain surface integrity. It’s about finding a balance that perfectly navigates the material’s requirements and the desired outcome.

Reference Sources

-

Development of optical fiber laser array method for assessing quality of chip packages?–

This paper examines the division of laser energy and its use in optical fiber systems.

-

Fiber Optic Instrumentation and Measurements?–

This document analyzes measurements carried out on fiber optics, particularly power measurement and fiber optic loss.

-

Laser Processing and Micromachining Solutions?–

This material discusses numerous technologies of laser machining such as laser marking and laser etching.

- Top Fiber Laser Marking Machine Supplier and Manufacturers in China

Frequently Asked Questions (FAQs)

Q: What is a split fiber laser marking machine?

A: A split fiber laser marking machine is a type of laser engraving machine that uses sophisticated fiber laser technology to mark or engrave materials, especially metals, with extreme accuracy. Its split MOPA (Master Oscillator Power Amplifier) configuration improves pulse duration control and peak power, thereby increasing the quality of engraving.

Q: How does a fiber laser cutting machine differ from a traditional one?

A: A fiber laser cutting machine uses fiber optics to generate the laser beam, making it more efficient than conventional laser machines because it can cut thicker materials. It is best for cutting and engraving metals because it cuts them faster and provides cleaner cuts.

Q: What materials can a fiber laser engraving machine work with?

A: A fiber laser engraving machine is designed primarily for metals, including stainless steel, aluminum, and brass. However, depending on the specific machine’s capabilities, it can also engrave on various other materials, such as plastics and ceramics.

Q: Can the 30W split fiber laser engraver for metal handle intricate designs?

A: Fiber laser engraving machines are designed to work mainly on metals like stainless steel, aluminum, and brass. However, other materials like plastics and ceramics can also be engraved depending on the machine.

Q: What is the benefit of using a rotary axis with a fiber laser marking machine?

A: A rotary axis allows the fiber laser marking machine to engrave cylindrical objects by rotating them during the engraving process. This feature is beneficial for marking items like bottles, pipes, and other round surfaces, providing a 360-degree engraving capability.

Q: What are the advantages of the JPT fiber laser over other laser marking machines?

A: The JPT fiber laser offers several advantages, including high speed, excellent beam quality, and precise marking capabilities. It also has a longer lifespan and lower maintenance costs than traditional laser marking machines, making it a cost-effective choice for businesses.

Q: How does the 20W split fiber laser perform compared to higher wattage models?

A: The 20W split fiber laser is ideal for lighter engraving tasks and softer materials, while higher wattage models like the 30W split fiber laser are better suited for thicker metals and more demanding applications. The choice depends on the specific engraving or cutting requirements.

Q: Is integrating a laser cutting machine with a fiber laser marker possible?

A: Integrating a laser cutting machine with a fiber laser marker can enhance operational efficiency. This allows users to switch between cutting and marking tasks without needing multiple machines, saving time and space in the workshop.

Q: What should I consider when looking for a laser engraving machine?

A: When looking for a laser engraving machine, consider factors such as the type of materials you will be working with, the required engraving speed and precision, the machine’s power output (like 30W fiber laser marking), and whether you need features like a rotary axis for cylindrical items.

- The Ultimate Guide: Fiber Laser Marking Machine with Rotary

- CO2 Laser Skin Resurfacing Benefits: Skin Treatment Options

- How Thick Can a Handheld Laser Welder Weld? Understanding the Capabilities of Laser Welding Machines

- Complete Guide: ATC vs MTC – Understanding Automatic Temperature Compensation and Manual Controls