CNC machines and CO2 laser cutters are arguably two of the most remarkable tools for precise cutting and engraving. However, like most high-precision technologies with different applications, they fundamentally operate in differing manners and have other uses. As a hobbyist, entrepreneur, or even a manufacturing expert, it is valuable to understand the difference between CNC and CO2 laser cutters so you can make an informed decision tailored to your requirements. In this article, we will discuss the operation of these machines, their advantages and limitations, and the scope of work they can optimally handle. Ultimately, this is intended to inform you which of the discussed solutions is ideal for your objectives.

What is a CNC Machine, and How Does it Work?

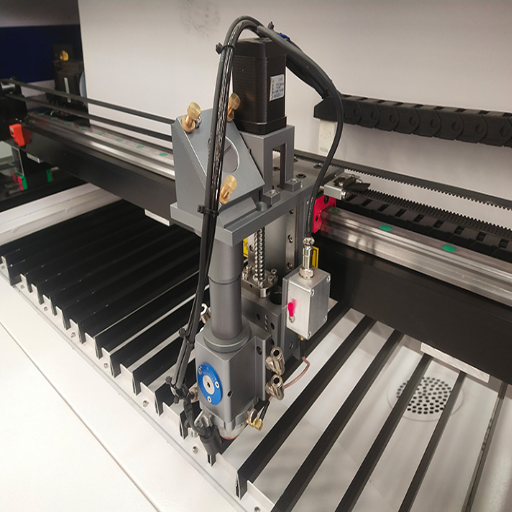

Your very own Computerized Numerical Control, aka CNC machine, is a device that cuts, shapes, mills, and even machined materials with high accuracy. It works on computer programming instruction sets prepared using specialized software. Based on the commands given to the machine, it mechanizes various operations using its tools. These tools can be drills, lathes, or milling heads. Sophisticated CNC machines can work with wood, metals, plastics, and other composites. This is why CNC machines are called “automated tools.”Automation in industrial machinery brings unprecedented levels of precision and repeatability. That’s why CNC machines have their place in every industry.

What are the key components of a CNC machine?

CNC machines have numerous components that CNC machine manufacturers meticulously design to enable automation and precision. The most critical machine parts include the following:

- Controller

The controller uses design files provided by the user to give tailored movement and operational instructions that the CNC machine can execute. It also serves as the machine’s brain. Modern CNC controllers are equipped with tools that enable advanced features such as tool path control and adaptive control of the CNC machine.

- Machine Bed

The machine bed is the foundation for the entire CNC machine, hence its name. It supports the workpiece and minimizes vibration while operations are ongoing for greater accuracy. A stable machine bed improves the CNC’s overall performance.

- Spindle

Cutting tools are powered and held by the spindle, which is a rotating part. Different materials require different cutting tools, so spindles differ in speed and torque. For lightweight materials like aluminum or even plastic, high-speed spindles are ideal, while harder materials require high-torque spindles.

- Guides and Bearings

These components make the movement of the machine on the various axes very smooth and precise. Proper machining processes require high-quality linear guides and bearings that are endowed with reduced wear and tear to minimize friction and add efficiency over time.

- Drive System

The drive system is responsible for moving the machine axes and uses motors, often servo or stepper motors. In high-speed machining processes, servo motors are used due to their greater accuracy and responsiveness.

- Cutting Tools

Material removal is accomplished by various tools, such as drills, end mills, or lathes. Different tools may be used depending on the finish quality of the workpiece and the material to be machined. Tools are usually made from tungsten carbide or high-speed steel for the best performance and durability.

- Coolant System

Maintaining tool and workpiece quality is equally important with CNC machines. The coolant system, for example, reduces tool and CNC machine overheating by dissipating heat, extending the lifespan of the two during the cutting operation.

- Work Holding Devices

These devices, such as vises and clamps, hold the workpiece in place while machining for greater accuracy. Vacuum tables reduce movement, which helps prevent machining errors.

- Feedback Devices

Both encoders and sensors can be classified as feedback devices. They provide real-time information regarding the axes’ position and tool movements. A CNC machine, for example, needs to know that the set parameters or instructions are being accurately followed.

- Power Supply Unit

The power supply maintains a machine’s consistent operational effectiveness by providing smooth and uninterrupted power to its individual parts and peripherals. Depending on the size of the machine or the complexity of the machining operations, intricate and large-scale machining projects must have top-of-the-line power supplies in order to achieve optimal performance.

An efficient CNC is considered one that comprises its subsystems into a single coordinated unit and is able to manufacture components with breathtaking degrees of accuracy. Current advancements in the Internet of Things (IoT) and Machine Learning deepen the capabilities of CNC machines by enabling real-time supervision, maintenance, and intelligent machining.

How does CNC cutting compare to traditional cutting methods?

Compared to traditional cutting methods, CNC cutting has many distinct advantages. For one, it is far more efficient, precise, and versatile. Unlike manual cutting, which requires human effort and is subject to many mistakes, CNC machines can achieve tolerances as tight as ±0.001 inches and maintain unrivaled accuracy for intricate designs. This sort of precision is especially useful in aerospace, automotive, and medical manufacturing, where performance and safety are fundamental because the slightest deviation could spell disaster.

The speed and productivity of CNC cutting are unmatched and are another key advantage. Manual sawing and milling often require significant time to measure, align, and execute. Because of the preprogrammed instructions, CNC machines can automate such processes with substantially reduced production time. For instance, complex parts can be produced in hours instead of days with traditional methods. Furthermore, modern CNC systems with multi-axis capabilities can perform multiple operations in one setup, saving labor and streamlining workflows.

Unlike traditional procedures, CNC cutting offers enhanced flexibility in the materials utilized. Metals, plastics, wood, and even composites can be used with Canadian National’s tools, showcasing their CNC tool’s versatile capabilities for various industries. For example, 5-axis CNC machines permit the intricate 3D cutting of materials like titanium or carbon fiber, which are challenging to work on with manual operations.

In summary, the initial purchase price of CNC machines is usually higher than that of other machines, but their value for money increases with the time spent using them. Automation cuts down on the amount of manual labor required and material waste, improving operational efficiency. Manual methods typically result in more significant material wastage due to lost parts and expensive labor in lengthy production cycles. Thanks to these advantages, CNC cutting technology addresses modern manufacturing problems more efficiently than other technologies.

What materials can a CNC machine cut?

The use of CNC machines has been on the rise in this technological era, and with their newfound versatility, they have made precision mass cutting in the woodworking, aerospace, and even plastic industries easier! These highly advanced programs can now process a wide range of materials, such as:

- **Plastics**: In the automotive and consumer electronics industry, plastics are contoured into parts like acrylic, polycarbonate, ABS, and even nylon, which contain custom partitions. They are used for more than just forming shapes. Even with elbows, CNC machining Prozac ensures leaves are cut and not warped on the surface, even when working at that level!

- **Wood**: With CNC machines, harder woods are no longer as restraining. CNC machines can now use Oak, Walnut, and even Maple to enhance furniture and decorative prototypes. Through CNC machining, old-school woodworking is out the door by allowing for intricate designs and vastly reducing the waste of materials.

- **Metals:** With efficiency becoming more pronounced, Aluminum, Steel, Brass, and even Copper are starting to be machined into CNCs. They are becoming increasingly crucial and easier to perform precision air contouring of space-grade titanium in aircraft and medical equipment. Some metals like Aluminum have become far more special due to their lightweight and ease of use.

- *Composites*: Carving strong, lightweight parts has been simplified with a method for CNC-carved fiber-reinforced composite materials such as Carbon Fiber and Fiberglass, which are very popular in the automotive and sports industries.

- Foam: CNC machines can process EPS, polyurethane, and other types of foam used for carving, packaging, and even sculpting. Specific parameters are set to avoid excess dust and deformation.

- Ceramics: Zirconia and alumina are advanced ceramics that can also be machined using CNC technology. The electronics, medical devices, and aerospace industries depend on these materials because of their heat—and shock-resistant properties.

CNC machines are designed to work with soft and hard materials, underscoring their versatility. The ability to work with various materials makes these tools essential in modern manufacturing.

What is a CO2 Laser Cutter, and What Are Its Advantages?

A CO2 laser cutter is a machine that engraves or marks various types of materials with a high-powered carbon dioxide laser. It precisely cuts wood, acrylic, plastics, leather, and certain metals, which can also be used for engraving.

Advantages of a CO2 Laser Cutter:

High-Powered Versatile Capabilities: It can cut or engrave wood, acrylic, plastics, leather, and even certain metals.

Desired Results: Unlike other cutters, CO2 laser cutters provide accurate results with class-A finishing.

Expandability of Scale: CO2 laser cutters are efficient for small and large-scale projects.

Non-Contact Waste-free: Avoids cut deformation that contributes to waste.

Flexibility Adaptation: Ideal for design, prototyping, and manufacturing.

Choosing CO2 laser cutters remains a popular solution for accuracy and laser-focused efficiency across industries.

How does a CO2 laser cutting machine operate?

Subsequently, CO2 laser cutting machines utilize an ultra-focused laser beam found within its parts, which is created from the electric stimulation of a combination of carbon dioxide, nitrogen, and helium gases in a laser tube. The mirrors and lenses then direct this laser beam and focus it on the material set to be cut. Once the laser beam starts to work, it creates temperatures of about 20,000 degrees Celsius at the focal point. The increasing heat of the laser beam melts, vaporizes, or even burns the material and creates exceptionally sharp cuts.

Modern CO2 laser cutters have sophisticated features such as computer numerical control (CNC) systems, enabling intricate cutting patterns and proposed resolution. Some CO2 cutting systems can obtain up to 0.1 mm tolerances, ensuring enhanced accuracy. Lastly, CO2 laser cutters can cut different materials like metals, plastics, wood, and glass at cutting speeds of 10 mm per second and more significant than 1,000 mm per second, depending on the thickness and type of material.

Using oxygen, nitrogen, or compressed air as auxiliary gases dramatically improves the cutting process by removing molten material and preventing oxidation from developing at the edges of the cut. To illustrate, laced oxygen enhances the cutting of thicker metals since it aids in combustion, whereas nitrogen makes cleaner cuts on materials susceptible to oxidation. With the integration of all the technologies and the precision engineering, CO2 laser cutting machines are guaranteed to be efficient and versatile for different industrial and artistic applications.

What materials are ideal for CO2 laser cutting?

CO2 laser cutting is a popular choice across many industries as it can work with many materials. Some of the most popular wood types used in CO2 laser cutting include:

- Wood—Aside from being one of the most common materials, CO2 lasers work tremendously well with plywood, MDF, and natural hardwoods. Precise and splinter-free engraving of intricate designs is possible with CO2 lasers.

- Acrylics and Other Plastics—Acrylic can sometimes be considered one of the most well-liked materials in laser cutting, as it is known for its clean and polished edge finish. Polycarbonate and PETG are other forms of plastic that can be used; however, they require extra care during the cutting process as they tend to melt.

- Textiles—CO2 lasers perform exceptionally well at searing the edges of intricate patterns designed on fabrics. Cotton, polyester, and felt are some materials that tend to work great with CO2 lasers.

- Leather – Unlike conventional methods, natural and synthetic leather can be cut and engraved using CO2 lasers. Because of this, it can be used in fashion and accessory design.

- Paper and Cardboard – Unlike traditional methods, CO2 lasers allow for detailed cuts and engravings on paper products such as invitations, artistic projects, and packaging prototypes.

- Rubber can be used precisely to make custom rubber stamps and gaskets, and CO2 laser cutting does the job adequately, offering precision and repeatable cuts.

- Glass and Ceramics—CO2 lasers are not the first choice when it comes to cutting surfaces, but they excel in surface engraving on glass and ceramics, allowing detailed etching for aesthetic reasons instead.

- Thin Metals—CO2 lasers do not work well with thick metals; however, when combined with other auxiliary gases such as oxygen for better cutting performance, CO2 lasers are efficient with thin sheets of aluminum or steel.

Due to its versatility, CO2 laser cutting machines are suitable for both flexible and rigid materials in industries like construction, fashion, manufacturing, and art. Last of all, data shows that CO2 lasers are still preferred for applications needing intricate details, thermal efficiency, and affordability.

What are the benefits of using a CO2 laser cutter?

CO2 laser cutters are cherished for accuracy, speed, and multifaceted usage in many circles. Each industry stands to gain from these attributes. One of the perks that stands out is the high degree of precision that can be reached and the detailed cuts that can be done at an elaborate level. This specialty is beneficial in use cases like manufacturing customized electronic parts. Also, CO2 cutters can manage various materials ranging from wood, acrylic, leather, and textiles to metals; this helps many businesses expand their offer.

Perhaps even more prominent than all other advantages is cost efficiency. In comparison to other cutting technologies, CO2 lasers have lower operational costs due to little maintenance and energy expenditure throughout their life cycle. Research suggests that productivity with CO2 laser cutters boosts by 30%, essentially improving efficiency, cutting waste, and reducing overall costs.

For fashion and other manufacturing industries, the ability to eliminate the need for extensive post-cut border smoothing is also a considerable plus offered by the combustive efficiency of the CO2 lasers. This ensures the cleanliness of the edge of the cut. Alongside those, modern CO2 laser cutters come with precision-improving automated systems, which further increase workflow pace for bulk orders. The versatility and reliability make the CO2 laser cutters a treasured item for countless activities.

What are the Main Differences Between CNC and Laser Cutting?

The methods and applications of CNC cutting and laser cutting are where these two forms of cutting differ the most. Metal, wood, and thick plastic CNC cutting uses drills or saws, resulting in the material being physically cut or shaped. Parts that need a lot of force or need to be cut from thick materials are done efficiently using this method. In contrast, other materials and intricate designs are cut using a focused laser beam, resulting in significantly more clean and precise cuts. Finer materials require more detail and finesse; softer metals, wood, and thin plastics are better suited for laser cutting. More materials can be used with CNC Machines, while laser cutting takes less time and gives more detailed results. Details and finishing touches are done differently with each type of cutting tool. With laser cutting, smoother edges are achieved without additional finishing work. While with CNC cutting tools, finishing processes must be done depending on the material and tool used.

How do CNC cutting and laser cutting processes differ?

Applications and Materials

The differentiating factor between CNC and laser cutting lies within the materials that can be processed and the applications. CNC cutting is highly adaptable and can process various materials such as metals, plastics, wood, foam, and composites. This makes it appropriate for use in aerospace, automotive, and furniture manufacturing industries, which extensively utilize various types of materials. Conversely, laser cutting is more suitable for thinner materials such as metals, plastics, acrylics, and wood, with mild steel being around 25mm and 15mm for stainless steel. Its precision is highly sought after for intricate pattern work in jewelry, electronics, and sign industries.

Precision and Time Optimization

Laser cutting offers unparalleled detail precision and is often more accurate in less intricate designs for detailed designs and small-scale projects. Laser cutting can achieve accuracy metrics of around ±0.1mm with clean and smooth edges, leading to no finishing issues. CNC machines also portray high accuracy values, typically ±0.02mm. However, compared to laser CNC machines, there is a great need for additional processes to achieve comparable materials, such as polishing or sanding. In 3D cutting tasks or high-volume production, general preference tends to lie under CNC machines due to their robust strength in handling denser and thicker materials, which results in faster removal rates.

Cost and Operational Effectiveness

These processes have clear cost differentiations that impact their usage. The difference in the materials directly affects the cost, which is more desirable due to lower energy consumption and maintenance. CNC cutting tends to gouge more in costs with the wearing out of tools and time spent post-processing the material. Laser cutting is better for providing value in small batch productions with exceptionally intricate designs, while uniform parts laser cutting is cheaper for large-scale manufacturing.

Environmental Considerations

About the environment, laser cutting has a possible advantage due to less material waste. The cutting of a laser produces minimal kerf or waste and, therefore, optimizes resource usage. Specific tools and techniques for CNC cutting, especially in milling or turning, can waste a more significant amount of material when compared to other methods. In addition, all techniques use dust or fume extraction systems specific to the process. Still, laser cutters, for example, may emit noxious gases when melting certain materials like plastics, so filtering systems are needed.

Having this information aids businesses in choosing the process that is best suited for their particular project requirements.

What is the cutting speed of CNC vs laser cutter?

CNC machines and laser cutters have a discrepancy in cutting speed, which is further determined by the thickness and the material being processed. Compared to CNC machines, laser cutters are faster, particularly with lightweight materials like paper and moderately thick plastics or metal sheets. For example, modern CO2 and fiber laser cutters can cut thin sheet metal at rates of 50 to 200 inches per minute, depending on the power of the laser and the type of material.

CNC routers and milling machines tend to function at slower speeds. However, with their high level of precision and versatility, CNC machines can achieve 10 to 50 IPM with denser or thicker materials, such as hardwoods and metals. Some of the factors that affect the speed include the cutter’s feed rate, spindle speed, and the hardness of the material.

Consider the advantages of laser cutters, such as their non-contact cutting, which enables them to cut at high speeds without tool wear or material drag. In contrast, CNC machines may need to work slower to maintain stability and prolong tool life when working with delicate deep cuts, thick materials, or complex shapes. These, alongside the type and thickness of the material needed, fuel the decision of what tool to use.

When should you choose CNC cutting and when should you opt for laser cutting?

CNC cutting and laser cutting both have their advantages depending on the project. CNC cutting, for instance, works best on thick materials, including metals, plastics, and wood, because it offers precision alongside material strength. CNC machines are standard in manufacturing because they carve, drill, and mill complex, durable components. For example, CNC cutting tools can process materials several inches thick, which is especially useful in the aerospace or automotive industries.

More delicate materials and intricate designs like sheet metal, textiles, or acrylics are better suited for laser cutting. It is the most accurate of all the cutting types, usually within +/- 0.1 mm, which is essential for electronics and jewelry. Lastly, laser cutting is beneficial for low-thickness materials, lowering the time needed for the entire project. For example, CO2 laser cutters can cut stainless steel or acrylics 10 to 20 mm thick and have clean, polished edges, which means no finishing is required.

Ultimately, deciding between CNC and laser cutting is based on the thickness of the material, the detail required, and how quickly it needs to be produced. Companies should consider these factors carefully to make the cutting technique appropriate for the intended project.

What Are the Applications of CNC and CO2 Laser Cutters?

Both CO2 laser cutters and CNC machines serve multi-purpose functions for different industries, including:

- Manufacturing

Helpful in creating accurate components, prototypes, and molds out of wood, metal, and plastic.

- Signage

Perfect for engraving and carving highly sophisticated signs and cutting signs for commercial and decorative purposes.

- Architecture

Valid in the creation of detailed models as well as customized building components.

- Jewelry Making

Perfect for intricate detailing and cutting of metals and other materials to create beautiful custom jewelry.

- Automotive

Helpful in cutting and shaping components with great precision.

These attributes show how efficiently they can serve a range of industry requirements.

In which industries are CNC machines commonly used?

The versatility of CNC (computer numerically controlled) machines makes them invaluable assets to various industries. Their efficiency, accuracy, and adaptability to complex requirements are only some of the factors that allow them to dominate several fields of manufacturing. Here are some of the fields where they create a huge impact.

- Aerospace: The industry heavily depends on CNC machines to construct physiologically crucial features of an aircraft, such as its engine, turbine, and various structural components. The degree of precision obtained by CNC machining allows them to meet the stiff aviation and space exploration safety and quality standards. The industry is also forecasted to grow due to the increasing global need for military and commercial aircraft.

- Medical: CNC machining is heavily relied on for making surgical instruments, dental prostheses, and even orthopedic implants. Due to its level of precision, it is incredibly useful in the medical field. When made using CNC, individualized medical devices such as implants ensure better patient health outcomes.

- Automotive: CNC machines are used for mass-producing parts of an automobile, such as the body, engine, and transmission. Their consistency and high quality make them invaluable in the automotive industry. Additionally, the innovative mechanical processes associated with the production of electric vehicles have increased CNC machining.

- Electronics: The demand for smaller, more efficient electronic devices grows daily. CNC machining enables the production of advanced components such as circuit boards, connectors, and enclosures. This industry uses CNC technology for its precision and miniature capabilities.

- Defense: CNC machining is used to manufacture firearms, ammunition, and tactical gear. Due to harsh conditions, the defense industry requires CNC parts of extraordinarily high durability and precision.

- Energy: CNC machines are also used in the energy sector, particularly to make parts for renewable energy systems like wind turbines and solar panels. CNC technology enhances the precision and reliability of such systems, maintaining their efficiency.

- Furniture and Interior Design: The CNC machine is a revolutionary tool in woodworking and furniture designing. It enables the production of decorative pieces, custom furniture, and intricate designs, increasing yield while reducing waste.

These industries highlight the flexibility and importance of CNC machines in contemporary manufacturing. With innovation in other fields, the advancement of technology will undoubtedly improve CNC machining.

What applications benefit from CO2 laser cutting technology?

Laser-cutting technology using CO2 is one of the best in terms of precision and efficiency, making it the best choice across industries. It is of utmost importance in the production of metal and nonmetal components. The ability to cut accurately and precisely through steel, aluminum, wood, textiles, and even acrylic allows CO2 lasers to produce intricate prototypes and parts.

The automotive industry fully uses CO2 lasers for engraving and marking car parts. Cutting of car interior panels and trims is easy and precise with CO2 laser cutting systems. At the same time, CO2 lasers are also utilized to mark and cut produced PCBs in the electronics industry. Accuracy in the micrometers range helps electronics function smoothly and ensures reliability when used in telecommunication devices and other consumer electronics.

Other than the above-mentioned industries, CO2 laser technologies have been extremely useful in the packaging industry as well. CO2 lasers help engrave complex logos and serial numbers onto packaging materials. Furthermore, they are also capable of creating precise openings. According to data collected from market surveys, there is a high demand for laser cutting, which is anticipated to exceed $7 billion by 2031.

The CO2 laser has also found applications in healthcare, including crafting sophisticated surgical instruments and implantable devices, which require precision cutting with lasers. The accuracy provided by laser cutting guarantees that these components of higher-grade medicine are filtered, cleaned, and polished to strict standards of hygiene and quality.

Conclusively, the efficiency and varied applications of CO2 laser cutting technology in different fields like industrial manufacturing, healthcare, and other sectors highlight its significance when considering its purpose. Other sectors are expected to adopt it so that they can capitalize on the benefits, and technological advancements will increase its use in the coming years.

How do CNC and laser cutting serve different fabrication needs?

The capabilities of CNC laser cutting and CNC machining differ in how each meets various fabrication demands. CNC machining encompasses a broad range of operations and is versatile enough to work with metals, plastics, and even composites, fabricating complex components with intricate detail. It performs remarkably well in producing mechanical parts, molds, and prototypes due to CNC’s ability to perform subtractive manufacturing processes like milling, drilling, and turning. Industries that heavily rely on dense materials and high durability with tight tolerances, such as aerospace and automotive manufacturing, are major consumers of CNC machining.

On the contrary, laser cutting is more about accuracy and speed in producing two-dimensional shapes and components. Focused beams of lasers or other high-powered energy devices cut engrave, or mark materials at exact levels. Laser cutting achieves the best results on thin to medium-thick sheets of metals, wood, acrylic, and textile fabrics. The electronics sector, the sign writing industry, and even the medical sector are keen on this technology because it enables them to create complex shapes with smooth contour edges while at the same time eliminating margins of error. Modern laser cutting machines can achieve tolerances of 0.001 and are suitable for any intricate and delicate work. New capabilities have emerged with technological advances in the laser cutting and CNC machining fields. Integrating CNC systems with CAD/CAM software leads to faster production times and the ability to create intricate geometries. In comparison, advancements in fiber laser technology have increased laser cutters’ cutting speed and energy efficiency, making them more effective for large-quantity production. Whether to use CNC or laser cutting technologies relies heavily on the project’s specific needs—if three-dimensional machining is required or if two-dimensional cutting with extreme precision is needed.

Which Machine is Right for Your Project: CNC or CO2 Laser?

Relating to your particular project needs, a CNC machine or CO2 laser can be chosen. Frequently used in woodworking, metalworking, and plastics, CNC machines are perfect for creating three-dimensional shapes, drilling, and milling due to their versatility with many materials. For detailed two-dimensional work that must be done on acrylic, leather, or thin wood, CO2 laser cutting would serve best. All the aforementioned factors can lead to faster production, especially if minute detail is a high priority. Assess the tasks involved in the project along with the materials to figure out which tool would be the best.

What factors should you consider when choosing between CNC and laser cutting?

There are several key principles to consider when comparing CNC and laser cutting techniques to ensure that the selection is the right fit for the project’s demands. The precision and detail required is one of the most critical factors. CNC cutting is perfect for complex three-dimensional shapes and thicker materials such as metals and hardwood because of its depth-cutting capabilities. Meanwhile, laser cutting is better suited for two-dimensional designs because of the high level of intricacies that can be achieved and the clean edges that can be produced on acrylics, thin wood, or fabric.

Material thickness and type are equally as crucial. CAD/CAM systems have greater versatility regarding material types and greater thicknesses. For example, CNC mills are capable of vertical cutting of steel blocks that are over an inch thick. However, depending on machine wattage, laser cutters operate more successfully with thinner materials, usually within the ?-inch to ?-inch thickness range.

The techniques also differ in terms of production speed. Laser cutting usually has faster processing times with excellent detail work and mass production because it does not require changing tools. With heavy-duty cutting and multi-dimensional designs, CNC machines are more efficient despite having a slower machining cycle time.

Another essential aspect to consider involves cost-effectiveness. The initial purchase of laser cutting machines is usually more expensive, but the operational cost is lower for thinner materials and simpler designs, resulting in more significant profit. CNC machines may be less costly at the start; however, ongoing costs vary with the materials and complexity of the project. For example, high-powered CNC tools may have significantly greater energy costs in processing dense materials.

Finally, safety and environmental factors should be considered for any business decision. Laser cutting minimizes physical waste but may emit fumes from the material being cut, requiring ventilation and filtration systems. CNC machines do produce chips and shavings that require cleanup but are not considered toxic. Assessing the workstation and applicable safety measures is essential to maintaining safe and efficient operation.

Balancing these factors—accuracy, materials, processing time, expenditure, and environmental impact—provides guidance for choosing the correct approach to a project, such as determining whether CNC or laser cutting is the more appropriate choice.

How does the budget affect the choice between CNC and laser machines?

Before investing in a CNC machine or laser cutter, it is essential to assess your budget, as both options have unique costs for acquisition, operation, and maintenance. Regarding CNC machines, the prices have a broader range: entry-level models start around $2,000, while industrial-grade models exceed $100,000. In comparison, hobby laser cutters start at $3,000, while industrial-grade systems go above $200,000.

The operational costs of laser cutters and CNC machines also differ significantly. It is common for CNC machines to require extra tools, bits, and maintenance supplies, which, over time, results in greater spending. With laser cutters, there is spending on consumables such as laser tubes and lenses. However, maintenance is less because there are fewer parts.

When considering efficiency, laser cutters outperform CNC machines for intricate and thin materials. However, laser cutters also NFC machines outperform for thick materials and large scale production because they are more durable and the tools used can be reused. The choice might also depend on whether there are existing financing options. Most vendors for both types of machines offer leasing programs or payment plans, which help buyers ease their upfront expenditures. Materials specifications, intended volume of use, and operational expenses over the asset’s life require particular attention if the intention is to draft a budget.

What are the long-term maintenance considerations for CNC vs laser cutters?

My experience with CNC cutters requires accurate performance cleaning, regular lubrication of moving parts, periodic tool changes, and thorough cleaning. Laser cutters, however, need special attention to their optical pieces, particularly mirrors and lenses that require regular cleaning and need to be replaced occasionally. Furthermore, in some cutters, the laser tube has a limited life span and may need to be replaced after heavy use, which may require some long-term expenditure. For both types of machines, proper maintenance schedules are fundamental to prolonging their effeciency and operational life.

Reference Sources

- Optimization of CNC CO2 Laser Cutting Process Parameters on Acrylic Cutting2:

- Key Findings: This study focused on optimizing the cutting parameters for acrylic using a CNC CO2 laser cutter. The Taguchi method, Grey Relational Analysis (GRA), and Response Surface Methodology (RSM) were used to determine optimal settings. The results showed that the best parameters for multi-objective optimization were 75% laser power, 5.9 mm/s cutting speed, and 3 mm nozzle distance.

- Methodology: The research used experimental setups to analyze processing time, dimensional accuracy, surface roughness, and carbon emissions. Mathematical models were developed for optimization.

- Top Co2 Laser Engraving Cutting Machine Manufacturer?And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is the difference between CO2 and fiber lasers?

A: The main difference lies in the laser source. A CO2 laser uses a gas mixture to produce a high-powered laser beam, ideal for cutting non-metallic materials. In contrast, a fiber laser uses solid-state technology, making it better suited for cutting metal and thicker materials.

Q: Can a CNC router be used for laser cutting operations?

A: While a CNC router can be equipped with a laser head to perform laser cutting, it is primarily designed for milling and engraving. A CNC laser cutter is more efficient and precise for dedicated laser cutting.

Q: How does the CNC cutting vs laser cutting process differ?

A: CNC cutting typically uses tools like routers or mills for material cutting, while laser cutting uses a focused laser beam to cut materials. Laser cutting is often faster and more precise, especially for intricate designs.

Q: Which is better for engraving: a CO2 laser engraver or a fiber laser?

A: A CO2 laser engraver is generally better for engraving non-metallic materials, while a fiber laser is more effective for engraving metals due to its high-powered laser beam and precision.

Q: What should I consider when choosing the right machine for my needs?

A: Consider the materials you will be cutting, their thickness, and the complexity of your designs. A CO2 laser machine may be ideal for cutting thin materials, whereas a fiber laser would be more suitable for cutting metal.

Q: Can I use a CNC laser cutter for three-dimensional cutting?

A: Yes, a CNC laser cutter can perform three-dimensional cutting, but the extent of this capability depends on the specific machine’s features and the complexity of the design.

Q: What types of materials can a CO2 laser machine cut effectively?

A: A CO2 laser machine effectively cuts non-metallic materials such as wood, acrylic, paper, and fabric. It is not recommended for cutting metal, which is better suited to a fiber laser.

Q: Is it possible to use a laser to cut materials other than metal?

A: Yes, laser cutting operations can cut various materials, including wood, plastic, glass, and fabric. The type of laser and the thickness of the material will determine the effectiveness of the cutting process.

Q: What are the limitations of a CNC router compared to a CNC laser cutter?

A: A CNC router has limitations in precision and speed compared to a CNC laser cutter. It may also struggle with intricate designs that require a high-powered laser beam for detailed cutting.

- 5 Common Types of CNC Machines: Understanding Different Types of CNC Machines

- Continuous vs Pulsed Laser Cleaning: How to Choose the Right Machine

- 5-Axis vs. 7-Axis CNC Machine: Milling & When to Machine

- Fiber Laser Cleaning: Laser Cleaning Machines & Applications

- Unlocking the Potential: How to Use a Laser Marking Machine for Engraving and Etching

- Learn the Main Distinctions: CNC Engraving and Laser Engraving

- The Ultimate Guide to Laser Cleaning: How This Revolutionary Rust Removal Technology Works

- Buying a Cheap Laser Cutter: Pros and Cons of Budget Laser Machines